【Articles】Understanding PCR: Applications, Advantages, and Maintenance FAQs

2026-01-12

Understanding PCR: Applications, Advantages, and Maintenance FAQs

Pressure Conductive Rubber (PCR) has emerged as a pivotal contact interface in the IC testing landscape. As advanced packaging trends pivot toward ultra-high density and high-frequency applications, PCR delivers a superior balance of electrical integrity, mechanical flexibility, and cost-efficiency required for next-generation semiconductor validation.

This FAQ guide addresses the most common questions on selection, application, and maintenance, helping test engineers achieve more efficient and reliable IC testing.

Q1: What is PCR, and how does it work?

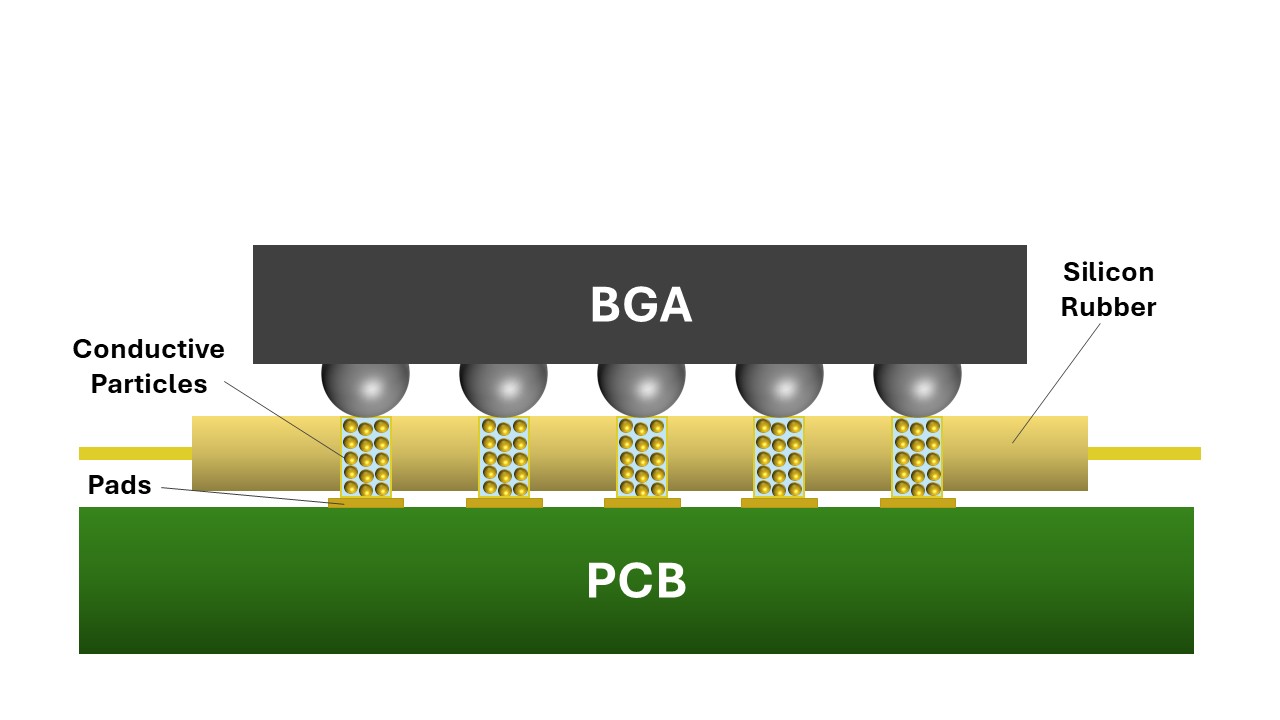

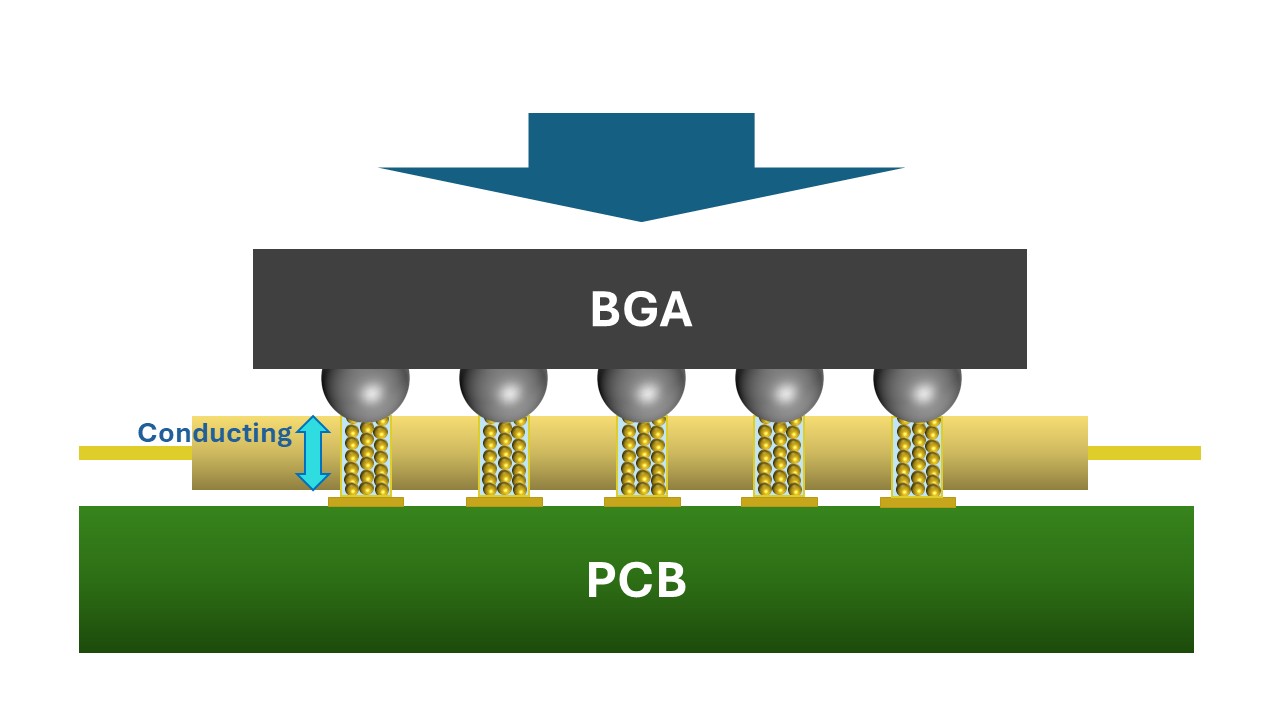

PCR (Pressure Conductive Silicon Rubber) is an elastic contact material consisting of a silicone matrix embedded with uniformly distributed conductive particles. In its relaxed state, the material maintains high impedance. When vertical pressure is applied, the internal particles interface to create a low-resistance path, establishing a stable, high-reliability electrical connection between the IC and the PCB.

Q2: What are the primary advantages of PCR?

Compared to traditional probes, PCR offers several benefits across diverse IC testing applications:

- Low contact resistance, ensuring high-fidelity, high-speed signal transmission

- Capable of handling high currents

- No solder ball marks or physical damage to the DUT

- Easy replacement without soldering

- Ideal for High Pin Count (HPC) applications; in high-pin-count scenarios, PCR conductive rubber offers a clear cost advantage over probe-based solutions

Q3: Why is PCR frequently adopted for high-frequency and high-speed testing?

As frequencies for 5G, AI chips, and mmWave applications continue to rise, PCR exhibits distinct advantages in high-frequency testing due to its structural characteristics:

- Shortened Conductive Path: The thin contact thickness of PCR significantly shortens the signal transmission path. This minimizes parasitic inductance and capacitance, vastly optimizing high-frequency signal integrity compared to the long travel distance of spring probes.

- Maintains Signal Integrity (SI): PCR utilizes a uniform conductive contact structure, which effectively reduces signal reflection and attenuation caused by impedance discontinuity at high frequencies.

Q4: What are the key applications of PCR?

In various applications, PCR serves as a high-performance alternative to traditional spring probes and is widely utilized across the following fields:

- Functional Test (FT)

- System Level Test (SLT)

- IC Validation & Debugging

- Automated Test Equipment (ATE)

- IC Programming

- R&D and Prototyping

Q5: What is the lifespan of PCR?

The lifespan of PCR—with industry field tests reaching tens of thousands to over 100,000 cycles—depends primarily on over-travel (OT), operating temperature, and cleaning frequency. Precise control of compression force to avoid excessive over-travel, combined with regular maintenance, is the key to ensuring long-term durability.

DediProg’s PCR solutions have successfully passed rigorous 100,000-cycle functional tests at leading OSAT, effectively enabling customers to reduce their total cost of ownership (TCO).

Q6: Which package types are best suited for PCR?

PCR is compatible with a wide range of packages, including BGA, QFN, LGA, and WLCSP. It is particularly ideal for delicate package types where protecting the solder ball structure is a priority.

DediProg possesses expert in-house design and manufacturing capabilities for PCR. If you have specialized testing requirements, please contact us. We are prepared to provide tailored, customized solutions based on your specific application criteria.

Q7: Are there any limitations when using PCR Sockets?

While PCR is highly versatile, certain scenarios require careful technical evaluation to ensure optimal performance:

- High-Temperature Environments ( >135 °C)

- Poor DUT Coplanarity (significant height variation across the solder balls or pins of the DUT)

These conditions can affect overall contact stability. We recommend a thorough technical assessment before implementation to ensure a reliable testing interface.

Q8: What technical specifications are required to select the right PCR solution?

To ensure we provide the most suitable PCR solution for your specific testing requirements, we recommend providing the following parameters:

- IC Package Dimensions

- Pitch

- Operating Frequency

- Current per Pin

- Operating Temperature Range

- Compression Force (Force-limit) Requirements

Based on these specific electrical and mechanical requirements, DediProg will deliver an optimized, custom interface solution tailored to your chip testing needs.

Q9: Can the PCR interface be repaired or replaced?

PCR is a replaceable consumable. When contact resistance increases or performance degrades over time, you can simply replace the PCR insert. Because the socket body remains reusable, this modular design effectively lowers long-term operational costs and minimizes waste.

Q10: What is the recommended cleaning method for PCR?

Over extended use, PCR may accumulate microscopic dust or solder debris, which can compromise contact stability. To maintain optimal performance, we recommend using a PCR Cleaning Pen to gently remove contaminants from the PCR surface without damaging the material.

Q11: Why should you choose DediProg PCR?

DediProg PCR = Rapid Customization × MIT Quality × IC Industry DNA

- Fast Customization Capabilities: We are one of Taiwan’s few manufacturers offering full PCR customization (Size/Pin/Pitch) with accelerated delivery schedules.

- Superior MIT Quality (Made in Taiwan): In-house design and production of pins, rubber, and sockets guarantee stable performance and cost-efficiency.

- Proven IC Industry DNA: Our PCR is utilized in-house for IC programming, ensuring rapid design iterations and proven long-term durability.

Read More:

The Engineer’s Guide to Pogo Pins: 15 Must-Know Q&As

Explore More:

PCR (Pressure Conductive Silicone Rubber)

PCR Socket

PCB/R Socket

Pogo Pin

Final Test Socket

Open Top Socket

DDR5 Module Test Socket

DDR4 Module Test Socket

Search and Order PCR Socket Online

Not sure which testing solution fits your needs? Please contact us for a free evaluation.

E-mail: sales@dediprog.com