【Articles】Auto IC Programmer Selection: Overview and the 4 Core Factors

2025-11-13

Auto IC Programmer Selection: Overview and the 4 Core Factors

Transitioning from manual to automated IC programming is a strategic investment that requires careful planning. While basic factors like initial price and local support are mandatory considerations, production managers must look beyond them, evaluating critical technical and operational criteria to ensure the chosen solution maximizes long-term return on investment (ROI) and prevents future bottlenecks.

Here are the key factors every production manager should consider when selecting their first automated IC programmer.

1: Define Your Output Requirements

Output requirement refers to your expected output volume , typically measured using the peak or maximum output your production demands. However, choosing a machine that simply matches your current output is insufficient; you should select a solution that accounts for future growth and incorporates operational overhead.

For example, if your peak output requirement per day is 20,000 units, the machine you select should be capable of achieving around 3,000 pieces per hour (UPH). This ensures stable operations and the ability to meet tight deadlines. This rough calculation is the starting point for narrowing down potential machine types.

2: Matching Machine Capability to Production Mix

Your production environment's unique characteristics—specifically the mix and volume of devices—must dictate the machine selection to ensure optimal resource allocation.

a. Low Mix, High Volume Production

If your production focuses on a small number of high-volume orders (e.g., 50,000 to 100,000 units of the same device), it’s best to prioritize systems designed for high throughput and long-term stability.

DediProg’s automated handlers, such as the DP1000-G5 and DP3000-G3 Plus, offer up to 32 and 96 programming sites, respectively. These systems are engineered to deliver reliable, high-efficiency performance throughout extended production runs.

b. High Mix, Low Volume Production

If your production involves numerous small orders, typically a few hundred to a few thousand units at a time, you need equipment that supports fast and efficient changeovers. Compact systems like the DP3T Plus are ideal for such environments, offering a streamlined workflow and rapid setup to handle frequent product variations.

3: Evaluating Input and Output (I/O) Mechanism Requirements

The chosen programmer should integrate seamlessly into your existing material handling process. Common input and output formats include trays, tubes, and tape.

Depending on your production setup, you may need peripherals such as tray loaders or taping machines. If repackaging is needed, for example transferring devices from trays to tape, include the appropriate peripherals in your production line to maintain a smooth workflow.

4: Identify Marking and Quality Needs

The production process sometimes requires marking on the devices and integrating quality control and traceability features directly into the programming process.

a. Device Marking Options

After programming, chips may require marking for traceability. Options include:

- Color/Ink Marking: A simple, cost-effective method for basic confirmation.

- Laser Marking: Requires more capital investment but provides high-precision marking for advanced traceability.

b. In-system Automated Optical Inspection (AOI) Options

In-system AOI is critical post-programming to catch defects. There are two distinct types of inspection, each addressing different quality risks:

- 2D AOI Inspection: This is a visual and positional check. Used to detect if orientation is correct in the output pocket and verify the correct marking.

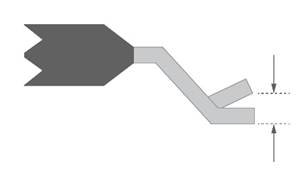

- 3D AOI Inspection: This inspection addresses physical defects. It is used to check for pin bending or co-planarity issues. A co-planarity issue, if undetected, will lead to weak soldering during the PCB assembly process, causing major production failures

The 3D inspection does not replace 2D inspection, as each evaluates different but equally critical aspects of the device.

Conclusion

Choosing your first automated IC programmer is a strategic decision that impacts the stability and cost efficiency of your production line. By looking beyond simple price comparisons, you can select a system that not only meets current needs but also supports reliable, cost-effective scaling for the future.

E-mail: sales@dediprog.com