【Articles】How to Choose IC Test Interfaces? PCR vs. Pogo Pin: Comparison of Electrical Performance, Lifespan, and Cost

2026-01-20

How to Choose IC Test Interfaces?

PCR vs. Pogo Pin: Comparison of Electrical Performance, Lifespan, and Cost

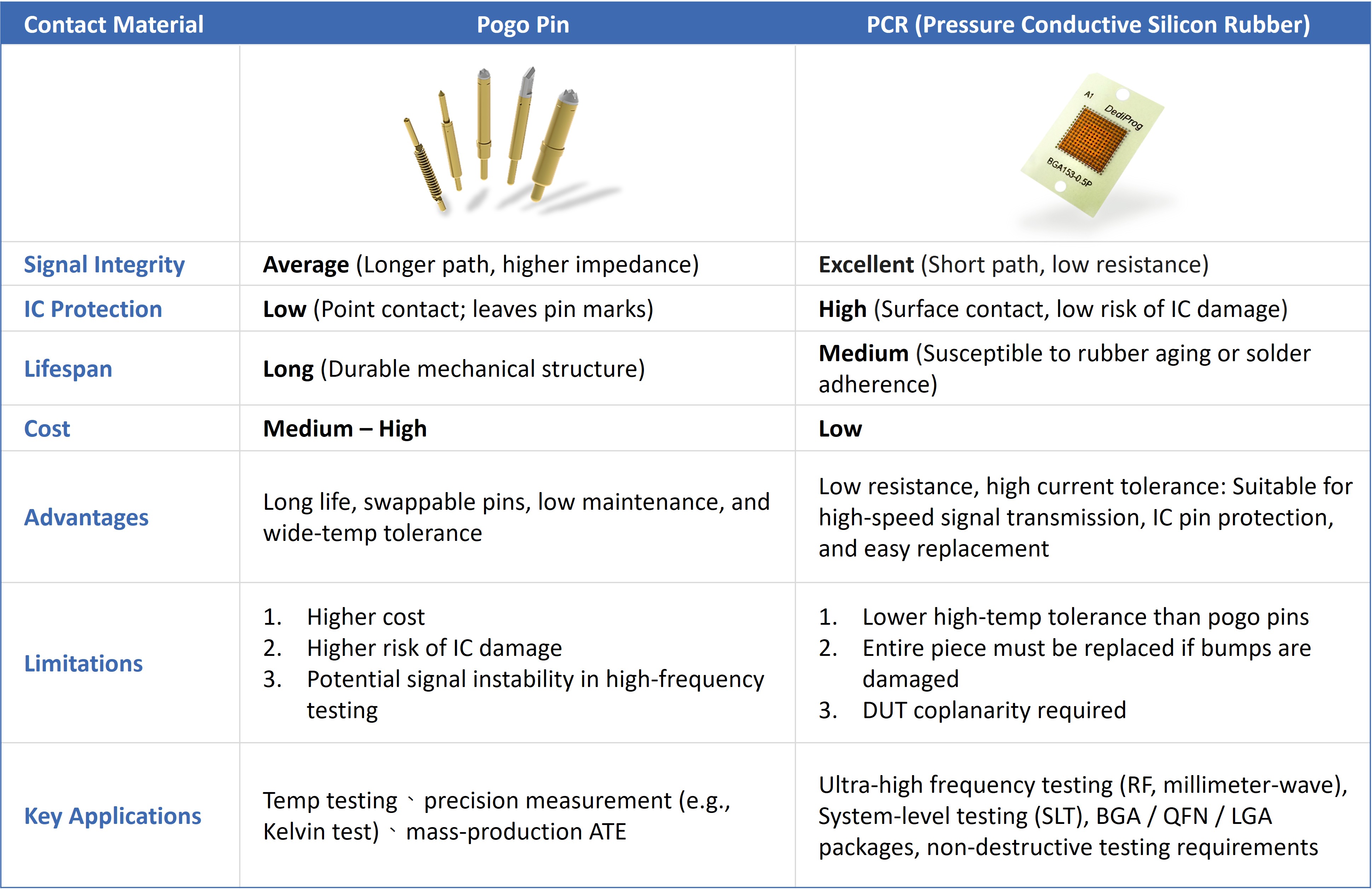

In semiconductor testing, IC programming, and system-level testing (SLT), the selection of the test contact interface directly determines test yield and overall cost. With chips evolving toward higher frequencies, faster speeds, and finer pitches, Pogo Pins and emerging Pressure Conductive Silicone Rubber (PCR) each offer unique, indispensable advantages.

This article provides a comprehensive comparison between PCR and Pogo Pins from multiple perspectives to help you select the most suitable contact solution for your test fixtures.

Pogo Pin vs. PCR (Pressure Conductive Silicone Rubber):

Q1: What are the differences in signal paths between PCR and Pogo Pins?

- Pogo Pin: Limited by its mechanical structure; signals must pass through multiple parts (plunger, spring, and barrel). This results in a longer physical path and higher self-inductance, which often leads to impedance mismatch and signal attenuation during high-frequency or high-speed transmission.

- PCR: PCR features a vertical conduction structure with a significantly shorter signal path. Its ultra-low inductance markedly improves Signal Integrity for high-frequency, RF, and mmWave testing.

Q2: Which contact interface provides more stable contact resistance?

- Pogo Pin: While Pogo Pins offer low initial contact impedance, repeated cycling can cause probe tip wear, surface oxidation, and spring fatigue. These factors lead to uneven contact force and increased impedance variability over time, making periodic maintenance or probe replacement necessary to maintain stable electrical performance.

- PCR: PCR uses a multi-point surface contact structure with evenly distributed conductive paths. Contact resistance remains stable even after repeated compression cycles, making it ideal for laboratory and validation environments that require high measurement consistency.

Q3: Which one has a lower risk of damaging ICs or solder balls?

- Pogo Pin: Point-contact design can leave marks on solder balls or pads and, in severe cases, damage the IC or interfere with subsequent SMT processes.

- PCR: The surface-contact design evenly distributes stress, protecting IC leads and package surfaces, and is ideal for testing high-value chips.

Q4: Which has a longer lifespan, Pogo Pins or PCR?

- Pogo Pin: Generally, Pogo Pins have a longer lifespan due to their durable mechanical structure. Individual probes can be replaced if damaged, making them suitable for high-cycle automated production lines.

- PCR: PCR’s lifespan is slightly shorter because silicone gradually ages over time or from exposure to temperature and solder residue. However, its simple structure and ease of replacement can make maintenance more efficient in specific applications.

Q5: Which is more cost-effective?

- Pogo Pin: Higher initial and maintenance costs, especially for high-pin-count or fine-pitch applications. While individual probes can be replaced, the large number of parts increases assembly and inventory complexity.

- PCR: Made from a single molded elastomer, PCR reduces mechanical complexity and assembly steps. For large-area, multi-point designs, it lowers development and tooling costs, making it the more cost-effective option.

Q6: What are the core application advantages of each?

- Pogo Pin: Pogo Pins offer a longer lifespan, are suitable for extreme high- and low-temperature testing, allow individual probe replacement as needed, and require relatively low cleaning frequency.

- PCR: PCR offers low resistance and low inductance, is ideal for high-speed and high-frequency signals, protects IC leads through surface contact, and allows for quick and easy replacement.

Q7: What are the main limitations of PCR and Pogo Pins?

- Pogo Pin: Higher procurement costs, risk of physical marks on ICs, and potential signal reflection or instability in high-frequency applications.

- PCR: Lower high-temperature tolerance compared to metal, partial damage requires replacing the entire piece, and requires a highly flat DUT contact surface.

Q8: How to select the appropriate contact material for different testing scenarios?

- Pogo Pin: Suitable for high-volume ATE automated testing, high-temperature burn-in tests, and Kelvin measurements.

- PCR: Ideal for high-frequency, RF, and mmWave verification, BGA/QFN/LGA package testing, system-level testing (SLT), and R&D environments that require frequent fixture changes.

Decision Guide: For projects with a limited initial budget and a need for rapid test deployment, PCR serves as an ideal starting solution. For ultra-high-volume production requiring exceptionally long fixture lifespan, a phased transition to Pogo Pins is recommended.

Read More:

Understanding PCR: Applications, Advantages, and Maintenance FAQs

The Engineer’s Guide to Pogo Pins: 15 Must-Know Q&As

Explore More:

PCR (Pressure Conductive Silicone Rubber)

PCR Socket

PCB/R Socket

Pogo Pin

Final Test Socket

Open Top Socket

Burn-in Socket

DDR5 Module Test Socket

DDR4 Module Test Socket

Search and Order PCR Socket Online

Not sure which testing solution fits your needs? Contact us for a free evaluation.

E-mail: sales@dediprog.com